LEADING MANUFACTURER, EXPORTER AND SUPPLIER IN INDIA

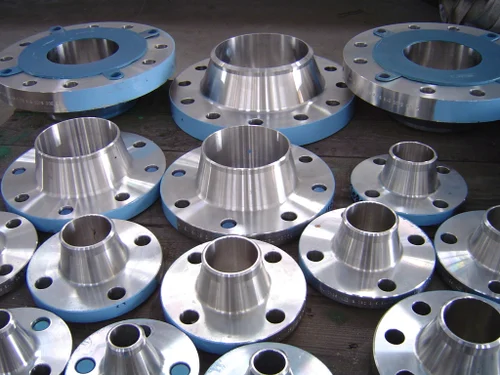

Sanjivini Steel Centre manufactures, stocks, and supplies 321 Stainless Steel Flanges in a wide range of sizes, shapes, and standards. SS 321 flanges are made of 18/8 ferritic steel strengthened with titanium. The chemical makeup of Grade 321 Stainless Steel Flange is similar to that of Grade 304 SS Flange, with the addition of titanium being the primary difference. The compound has a yield strength of 30 kg and a basic tensile strength of 75 kg. The stainless steel UNS S32100 Flange is a type of pipe closure flange. These SS 321 flanges are resistant to corrosion after being processed in the carbide deposition range of 425 °C to 850 °C. The 321SS Flanges are the optimum answer for projects that demand

The 321 SS Flanges are the ideal choice for programs that require a temperature range of up to 900 °C. The SS 321 Flange is comprised of stainless steel and is used for high-temperature applications. The composition is more corrosion-resistant than the 304, 316, and 310 stainless steel grades. UNS S32100 stainless steel pipe flanges are commonly used in pharmaceutical, food, saltwater, marine, and other structural application

The pressure standards for 321 Stainless Steel Flanges range between 150 and 2500 pounds. The Stainless Steel UNS S32100 Flange, like other austenitic grades, offers excellent forging and soldering qualities. The SS 321 Flanges are easily crushed or roll formed, and they offer excellent solderability. The composition does not require annealing after welding. Even at operating temperatures, the 321 Stainless Steel Flanges are remarkably durable.Sanjivini Steel Center stocks, manufactures, and supplies a wide range of Stainless Steel 321 Flanges, including SS 321 Large Diameter Flanges, SS 321 Sorf Flanges, SS 321 Blind Flanges, SS 321 Table Flanges, SS 321 Weld Neck Flanges, SS 321 Flanges, SS 321 Slip-On Flanges, SS 321 Socketweld Flanges, SS 321 Plate Flanges,

Numerous industries and applications use our SS 321 flanges. Here are a handful of them:

Oil & Gas Industries

Chemical Industries

Petrochemical Industries

Marine Industries

Refinery Industries

Power Plant Industries

| Specification | ASTM A182 / ASME SA182 |

|---|---|

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 ASTM A182 F321 Stainless Steel Flanges |

STANDARD | WERKSTOFF NR. | UNS |

SS 321 | 1.4541 | S32100 |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) – 0.70 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| The American Society of ENGINEERS (ASME) |

|

|---|

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab reports, Destructive Test Report, Non Destructive Test Reports

Packing In Wooden Boxes, Plastic Bags, Steel Strip Bundled, or as per Customers Requests

Sizes and Specifications other than above can be manufactured on request

FOR MORE DETAIL OR ANY BUSINESS ENQUIRY PLEASE FILL TO FREE CONTACT US

24/7 Support for Your Business

LEADING MANUFACTURER, EXPORTER AND SUPPLIER IN INDIA

©2024 SANJIVINI STEEL CENTER Powered By YUGASMI

About Us

We specialize in exporting a premium selection of Stainless Steel, Carbon Steel, High Nickel Alloy, along with Pipes, Tubes, Fittings, Flanges, Fasteners, and more.

© 2024 SANJIVINI STEEL CENTER Powered By YUGASMI